The refractory products are selected from the principle of selection of mono aluminum phosphate. Especially non-fired refractory products and unshaped refractories. Their mechanical strength (structural strength) is mainly provided by it. However, there are many kinds of them for refractory materials, and the bonding mechanism is also different. Therefore, in actual production and use, suitable one should be selected according to refractory material, molding or construction method, and use conditions. The selection principles are as follows:

The nature of it must be compatible with the properties of the refractory material being bonded. For example, the Kelly kiln considers acidic, neutral and weakly alkaline dihydrogen phosphates for acidic and neutral refractories. For alkaline refractory materials, acidic mono aluminum phosphate cannot be used directly. Neutral or alkaline mono aluminum phosphate can only be used. If it is used under reducing conditions, organic mono aluminum phosphate with high residual carbon can also be used.

It should be compatible with the molding method or workability (construction performance) of the material. The fired refractory products generally use temporary one (such as lignosulfonate). While the non-fired refractory products generally use chemical one (such as aluminum dihydrogen phosphate, water glass, etc.). Condensed and hardened one at room temperature, such as hydration-bonded, or chemically bonded (hardener), or agglomerated (additional)one, ramming and plastics Adhesive bonded or chemically bonded, or ceramic bonded one is used; and the sprayed refractory material may be selected from aluminum hydride similar to the cast refractory.

It must also be compatible with the high temperature performance of the material, and should not reduce or reduce the high temperature structural strength, corrosion resistance (corrosion) and slag resistance of the material. For high alumina or clay castables, ordinary calcium aluminate cement or mixed clay can be used as aluminum dihydrogen phosphate, and corundum or corundum spinel castables should be pure calcium aluminate cement or activated alumina. It can be used as aluminum dihydrogen phosphate.

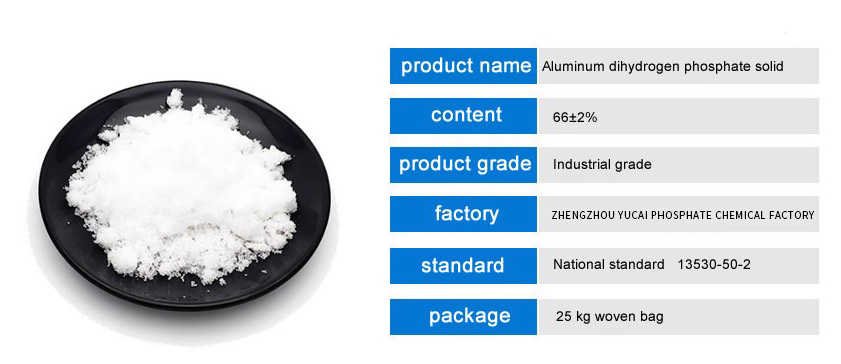

We Yucai Chemical factoty have summed up a lot of market experience and have excellent teams to provide the best service and quality. We have many customer use cases and sincerely look forward to your opinions or questions.

https://www.cnycchem.com/product/liquid-aluminium-dihydrogen-phosphate/

Henan Yulin Chemical Co., Ltd

Henan Yulin Chemical Co., Ltd